Best way of use Double layer roll forming machine

Throughout the long term, individuals have found and learned new things to make things a lot more straightforward to do. Cycles, for example, metal framing used to be very hard to achieve in light of the extremely restricted information and hardware accessible to them. Luckily, all the difficult work and constancy of man paid off, on account of their endless desiring for information and data. These days, we see a ton of materials and products made out of metals. The Iron Age time frame resembled the impetus that drove us to what we are currently The ancient men’s utilization of steel and iron as weapons and instruments filled in as the establishment to the more intricate and complex cycle that we presently call metal shaping.

Metal framing alludes to any interaction that includes embellishment or molding a particular sort of metal into an ideal structure. Shaping is characterized into five gatherings. In the first place, there is mechanical working, which is the most well-known among the five. This incorporates measures like drawing, producing, rolling, expulsion and some more. Different classifications are projecting, electroforming, fiber and powder metal shaping and joining.

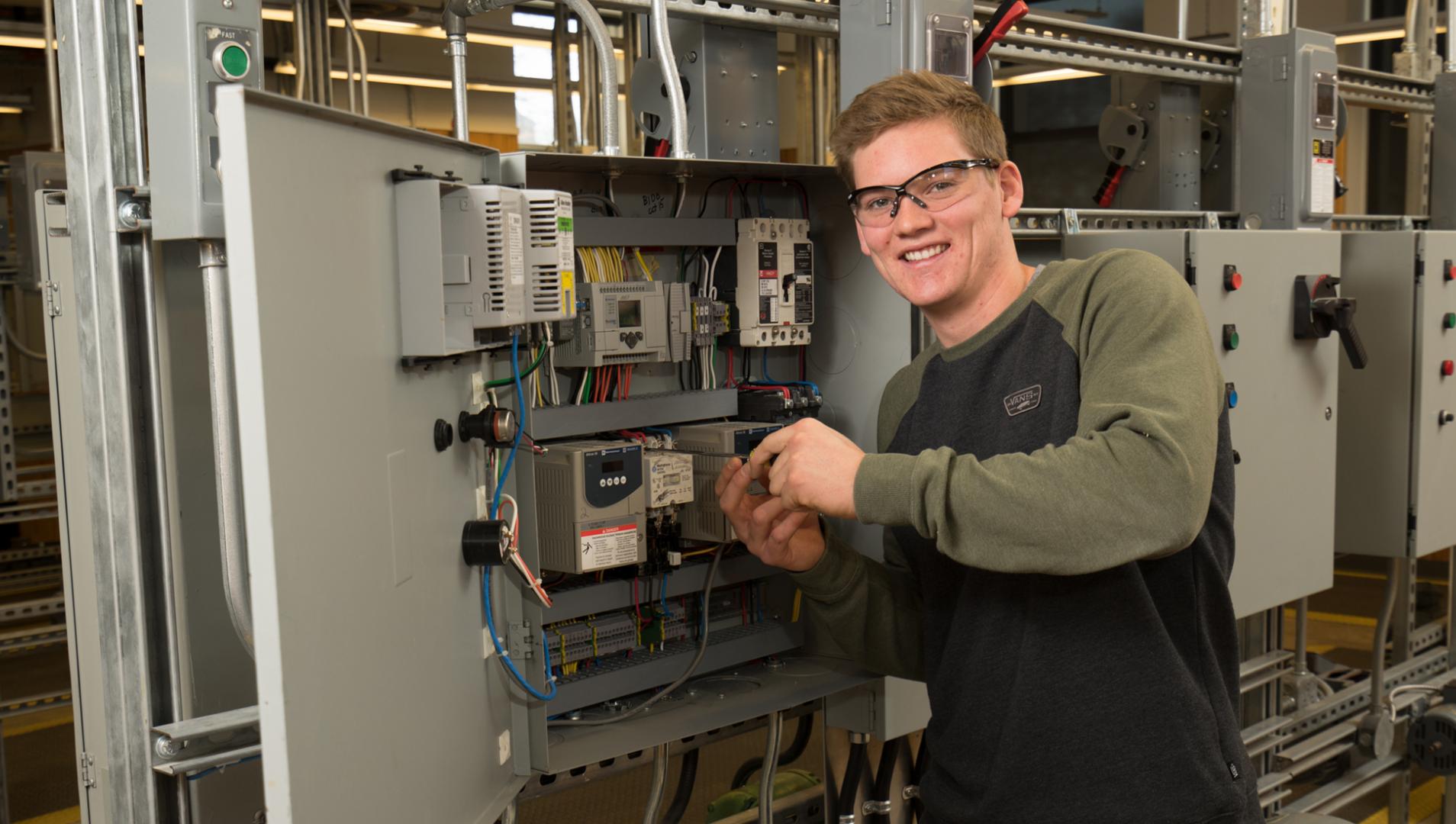

In metal framing, there are a few sorts of hardware utilized. Recall that it is a cycle that reshapes a metal. So an apparatus that is durable and sturdy enough to have the option to make sufficient power to cause an adment of the type of the metal is required.

Quite possibly the most normally utilized is the may can tole metal-collapsing machine. It is simpler to deal with contrasted with the others. You, being the administrator, need not apply an excess of exertion to make it work. The machine is adequately proficient and is protected to utilize.

Another metal shaping hardware is known as a roll-twisting machine. This machine has somewhere in the range of two and four moves that turn close to one another. At the point when a metal is embedded between the rollers, the metal is bowed into either barrel shaped fragments, circular portions, cones or straightened surfaces. A point bowing machine is more engaged in making completed items that are underlying formed like shafts, square cylinders, aluminum expulsions and channels. It comes in three-roll single or twofold squeeze types, four roll types, even roll types, and the sky is the limit from there. Obviously, regardless of whether you are in control of these machines, you ought to get familiar with the methods on the best way to appropriately continue with the interaction of metal shaping. Factors like exactness, accuracy, situating and more ought to consistently be mulled over.